Description

*NOTICE This product does not ship to LA County, Riverside County, Orange County and San Bernardino County California.

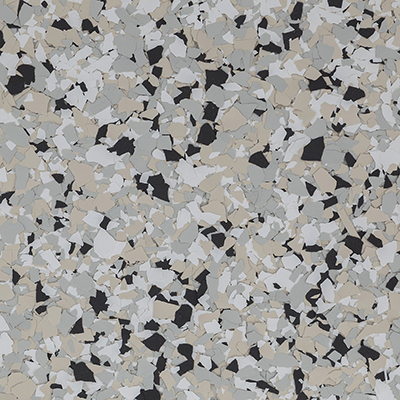

This is the 100% opaque pigment pack that is added to the Sweet Concrete Coating®. This pigment works well (mixed with the sealer) as a base coat for polymer flake and quartz granule systems. It can also be used as a base coat to create a solid colored floor system. See color chart below for color options.

Sweet Concrete Coating® is a ready to use, easy to apply, fast curing, clear polyaspartic / polyurea surface coating. This industrial strength coating can be applied interior or exterior in residential, commercial, or industrial settings. Pigment packs can be added if an opaque color is desired.

- High gloss and 100% UV stable.

- No primer required.

- No mixing required (unless adding the pigment pack)

- Fast curing, multiple coats can be applied in one day.

- Works well with polymer flake broadcast.

- Highly chemical, heat, and scratch resistant.

- Easy to apply using only paint rollers.

Sweet Concrete Coating® solves issues associated with other polyaspartic systems by eliminating pot-life issues because no mixing is involved… meaning the product will not begin to cure until it’s been applied. Sweet Concrete Coating® has excellent self-leveling capability and is tack free in 2-4 hours. This sealer can be used as a stand alone clear coat to be applied over prepared concrete, or stained concrete. It can also be used as base coat and / or topcoat which means no primer is required. Sweet! Convenient color pigment packs can be added to clear Sweet Concrete Coating® to provide a durable color base coat. Polymer color flakes, quartz, mica, and polymer flake blends can be broadcast into the colored base coat. Non-slip media can be mixed into the top coat to increase slip coefficient properties.

Question: Is Sweet Concrete Coating® more hazardous than epoxy or other polyaspartic / polyurea products?

Answer: No, the hazard ratings on most coating products used for garage floors or concrete coating projects generally have the same rating. Sweet Concrete Coating® has a lower reactivity level then other products because the reaction of the product is 90% completed during the manufacturing process. Any exposure to a chemical reaction is almost eliminated, the solvent evaporation allows the product to fully cure. In other words when two part systems are mixed on site, 100% of the reaction happens right then and that means more harmful chemicals are released on site.

Approximate coverage: 2.0 Mils = 500 sq.ft. / 4 Mils = 250 sq.ft. / 8 Mils = 125 sq.ft.