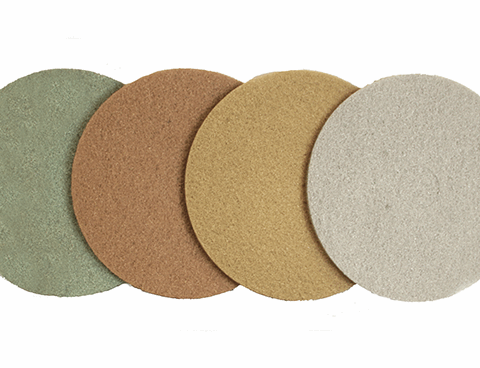

Description

Premium 8 Segment Transitional Diamonds

Made with Blue Star Diamond Technology™, Premium 8 Segment Transitional Diamonds are designed to transition from a metal diamond grinding process to the resin polishing process. With more surface area, they won’t cut as fast as the Premium 4 Segment Transitional Diamonds but will leave the floor smoother. This technology is a unique ceramic bond matrix that holds the diamond particles together. Therefore, it gives you a long lasting and efficient polishing pad.

This pad eliminates metal bonded scratches during the floor polishing process. Refining metal scratches improves the longevity and reflectivity of the floor so you can achieve the best quality finish. Thanks to the ceramic bond of the Blue Star Diamond Technology, you can skip the traditional last metal step and still efficiently remove those difficult metal scratches. It also saves time by removing the scratches in just one or two passes versus the five or six passes a resin-bonded pad would require.

American Made

Above all, Boride’s Premium 8 Segment Transitional Diamonds are manufactured in America. Therefore, by using these great diamonds you’re supporting fellow Americans and American manufacturing! As a result, these diamond pads are of a far superior quality compared to diamonds made in China.

Note that this diamond should not be used on concrete floors with cure and seal, mastic, or to remove coatings.

More Info:

- Purpose: Eliminates metal bond scratches and hones your floor in preparation for the polishing steps

- Flooring types: Soft, medium and hard concrete, plus terrazzo and overlays

- Grinding types: Wet or dry

- Machine compatibility: Small, medium and large planetary and rotary machines, including the Hawk BRUTE

- Mounting style: Velcro or boss/velcro (BOSS VELCRO IS ONLY USED WITH THE BORIDE ADAPTOR SYSTEM)

- Expected lifespan: 15,000-25,000 sq. ft.

- Available Grits: 30, 50, 100, 200, 400

- Grade: Soft, medium, or hard

- Pad size: 3”