Description

Extreme Penetrating Sealer

Concrete Chemistries new Extreme Penetrating Sealer is impressive. See, there’s a lot of concrete damaged from the freeze thaw cycle in the area my local company services. The EPS has become the main sealer to mitigate this problem for my clients. It increases the density of the substrate and permanently waterproofs it at the same time. This strengthens the concrete and increases the longevity of your investment. In addition, it wont change the look of the concrete and won’t leave a powdery residue on the concrete like other penetrating sealer do.

It blocks the moisture from getting into the concrete thus preventing the expansion and contraction caused by freezing and thawing. It also protects the concrete from damaging road salts and ice melt products which is great.

Since EPS increases the density of the concrete it can be used during the polishing process as well. I usually add it after the I’m done with the lower grit levels and I also add it right before the final step of the polishing for maximum protection and shine enhancement. The great thing about it is that it migrates deeper into the substrate compared to traditional desifiers. It also is permanent so it doesn’t have to be reapplied every couple of years. Therefore, it’s a better solution for your concrete.

More About The Extreme Penetrating Sealer

Concrete Chemistries EPS is a non-toxic, fast drying, reactive densifier for concrete and masonry surfaces. It offers excellent penetration, increased hardness, high durability, and strong chemical / abrasion resistance. Due to EPS’s advanced nano-quartz formulation, concrete and masonry surfaces become stronger, look better and are easier to maintain. An excellent choice for anywhere permanent waterproofing and fortifying of concrete is required.

Extreme Penetrating Sealer is meant to be a stand alone sealer, meaning NO SURFACE SEALERS CAN BE APPLIED OVER THE TREATED CONCRETE. If you would like to increase the density of your concrete before applying a surface sealer or coating please use Creto DPS.

How To Use

Use on concrete, brick, terrazzo and other masonry surfaces.

COVERAGE: Approximately 200 to 500 sq. ft. per gallon. Coverage will vary depending on the porosity of the substrate.

HANDLING AND STORAGE: Close container after each use. Store in original container only. Keep in a cool, well-ventilated area. Avoid freezing or high temperature long-term temperature storage. Keep out of reach of children.

DIRECTIONS:

1. Ensure surface is clean, sufficiently dry and free of waxes or coatings. Drying times after cleaning may vary due to local conditions. Do not apply while surface is wet.

2. Apply EPS liberally using a low pressure sprayer, paint pad, roller, brush, lambs or wool applicator. Distribute product evenly over entire surface to ensure uniform coverage and maximum penetration. *Note: Do not allow excess sealer to dry on surface. Roll out any puddles from an uneven surface.

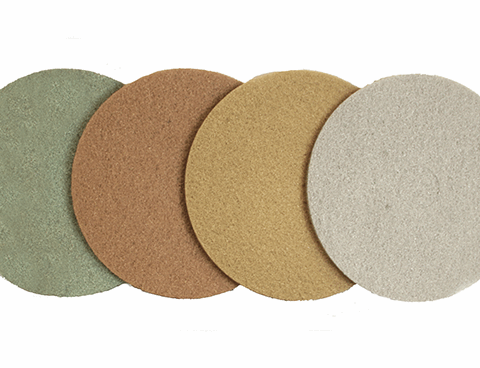

3. Allow EPS to dwell for up to 20 minutes, or until it begins to dry on surface. Remove and excess with cotton bonnet pad or clean towels, until surface is completely dry.

4. Apply a second coat if necessary, no later than 30 minutes after initial application.

ADDITIONAL INFO:

For outdoor applications, do not apply in temperatures below 50 or above 90 degrees. During the hottest months, it is recommended to apply in the early morning when the surface is at its coolest.

Ready for foot traffic in 2 hours. IIt’s fully cured in 12 – 48 hours depending on the temperature.

Clean tools with water.

SUBSTRATES:

EPS can be used on concrete, brick, pavers, and natural stone tile.